The Hip Monsters team was thrilled to be invited to a Maker Fest last week at Ecole Bilingue in Berkeley, CA. Ecole Bilingue is a preschool to eighth grade French immersion school focused on preparing their students to make a positive impact on the world.

We had a wonderful time at the maker fest and it was amazing to see such talented makers and dedicated students. The event had great food (including handmade boba tea), a fun crowd, and an exciting lineup of makers. It was a beautiful day in Berkeley which added to the cheer.

Below are just some of the makers at the festival.

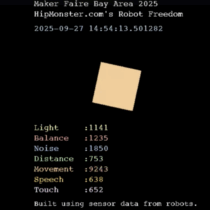

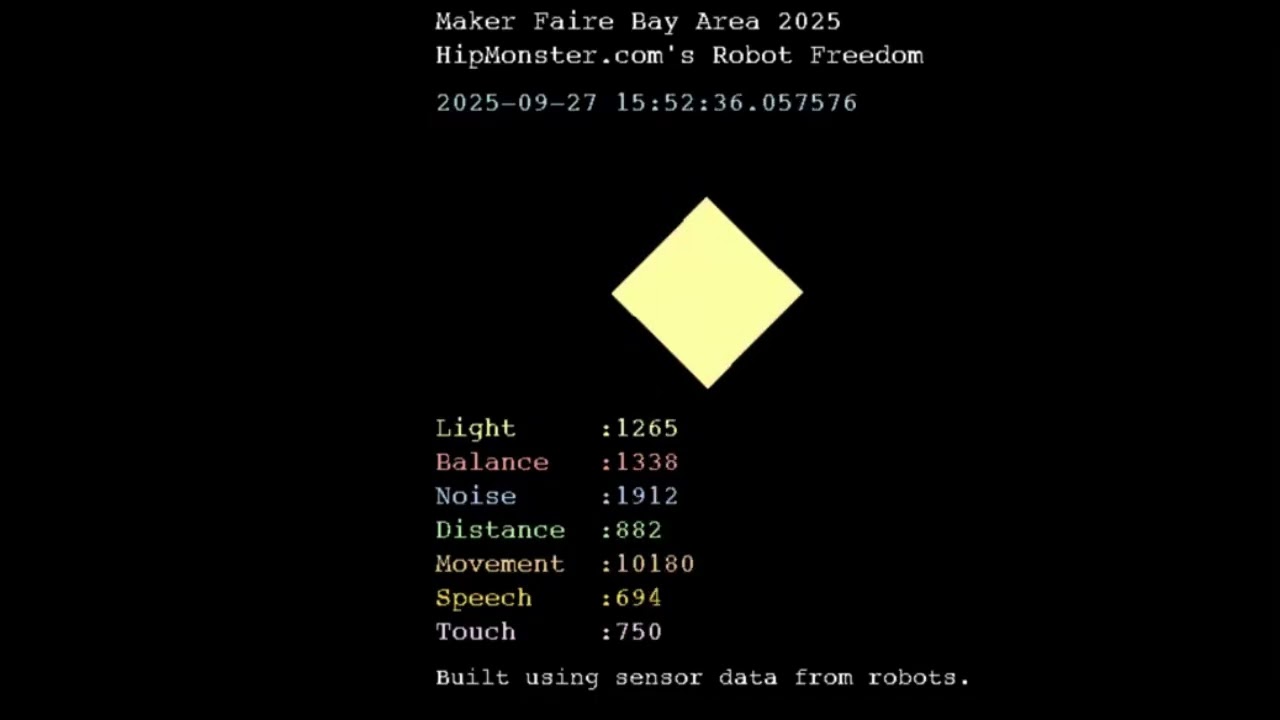

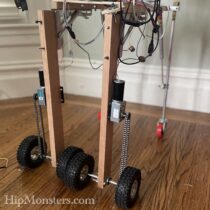

Hip Monster’s Robot Freedom

We were there with Number Three of RobotFreedom, who got a chance to test out her new legs. We will have a post in a bit on her leg redesign. The legs worked well and the batteries lasted longer than we anticipated.

We also brought our pneumatics demonstration which is an ideal place to start kids (and adults) on robotics.

The Sewing Corner

There was a great sewing section with helpful makers who quickly got even first time sewers make a tote bag.

Here is a finished toto bag! We have already put it to good use storing cat toys.

Magnification Mayhem vs. Resolution Rumble!

George and Janai Southworth from the San Francisco Microscopical Society had a fantastic demonstration of microbiology. They showed how different filters and lightning impacted what could be viewed through the microscope. Below is a petri dish of bacteria waiting to reveal its secrets.

Solar Racing Car

Members of the UC Berkeley CalSol Solar Racing Car were there giving us the inside scoop on their upcoming race in Nashville, TN. Every few years the car is completely redesigned and rebuilt using the most up to date technology.

3-D Print Making

There was 3D printing space with a great collection of designs and examples. All the designs were coded by kids!

Here is our favorite creation, a 3d printed pink rabbit.

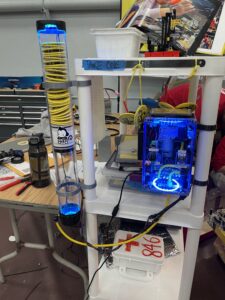

Bike Powered Smoothie Machines

The bike powered smoothie machines were steampunk inspired pieces of art. They were designed and made by the talented students at Ecole Bilingue. They also are a great way to make sure you earn those calories in the smoothie. Every household should have one of these!

The designs are modified stationary bike with blender connected to the front wheel.

Here are the bikes in action making a smoothie.

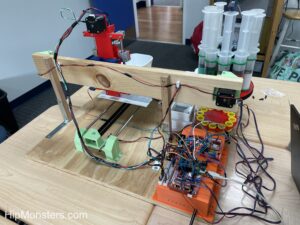

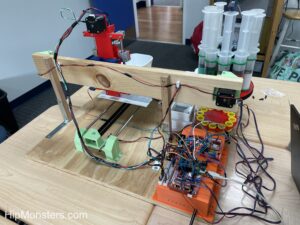

Painting Robot

They even had a robot making art! It was fun watching the robot as it dutifully created its next masterpiece.

Here is a view of the business end of the painter bot.

Space Wars

And last but not least, a RaspberryPi powered game console designed and built by one of the students. The compact design had custom made controllers that allowed for two person games.

The stand was a clever design using a cardboard box as a case neatly cut so it looked.

Thank you so much to Ecole Bilingue for inviting us to the maker fest! We would love to participate in more of your events in the future.

Hope you find inspiration!