The HipMonster.com’s team was invited to do a middle school robotics presentation last month to show kids the fun side of robotics and technology. The audience was so awesome and engaged making it a fun experience for everyone.

The theme was how to take over the world using robots, making it fun to keep the students engaged. We used a steampunk template for our slides to match our robot designs and channeled Girl Genius when presenting.

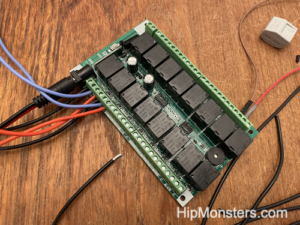

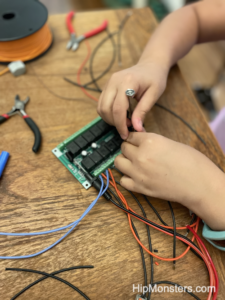

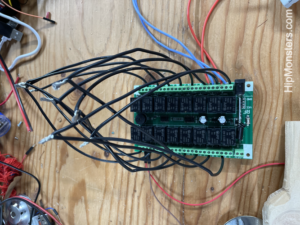

The robots got banged up a bit in transport but nothing completely broke. The biggest issue was the wires getting pulled out from the Arduinos. Luckily, it was only the breadboard jumper wires which are easy to put back in place. None of the soldered wires were broken which could have been very hard to fix. Breadboard jumpers are designed to be repeatedly taken on and off. They are like tiny USB cables and colored which helps see how what each cable is connected to (this is important because sometimes you can have dozens of wires). When you solder a wire to a controller it can only be broken to be removed. You solder wires by using melted metal called solder and a really hot device to melt the metal. When a solder connection breaks you need to melt the metal again to reattach.

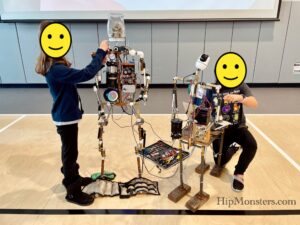

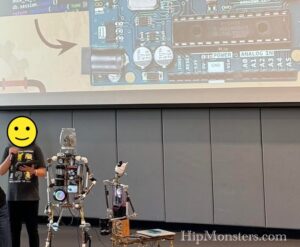

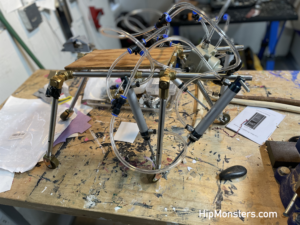

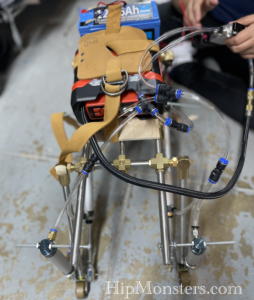

Here we are putting the finishing touches on Number Two and Number Three. All the robots traveled well and were up in running in thirty minutes except for one whose battery was faulty. When transporting batteries, we take extra care not to damage them and use a special carrying case.

We wrote a quick intro for the robots to perform to set the mood. After the intro, we dove right into robotics.

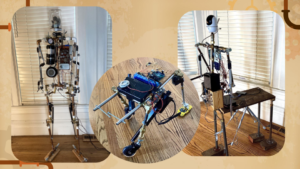

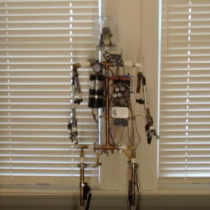

Here are three robot bodies. The first is Number Three. She can move his arms and hands, and talk. The middle is called Number Five. He can walk forward on his own using his four legs. The last is Number Two. He can’t do much, but he can still talk and move part of his arms.

For each robot body, you need to do several things. There needs to be a skeleton, a power source, and something that makes the robot move. When we are thinking of designs for our robots we often think of animals that already exist. We also take inspiration from robots in different books and webcomics.

Number Four is the most complicated one. It took us over one year to build her, and she is still being modified. Many other robots were also not built all at once but were gradually assembled as we got new ideas.

After you build the body, you have to give the robot a brain. in our robots, we use something called an Arduino.

It is basically a tiny computer that you can program to do different things. For our robots, we use Arduino to make the robot walk on its own, so we don’t have to use a remote control. For one robot, the Arduino can also choose the direction that it walks in, and how fast it walks. You can find a simple example here.

We code the Arduino from our computer, then the Arduino sends messages to the robot to control it. We edit the code based on our observations and new ideas.

We have many different types of robots that can move their whole body, each type demonstrates a different way of moving. We have the 4-legged walkers, which are our first moving robot design. They are made of metal pipes and have four legs and wheels for feet. We put wheels on their feet because we wanted less resistance and friction, but we didn’t want the robots to just be like a remote-controlled car. We wanted them to walk. The design of the legs and the “knee” has made a big difference.

Another design is our Seal robot. This one is very different, as it only has two legs and no wheels. The legs pull themselves forward, powered by linear actuators. To make sure that the legs don’t just go backwards and stay in place, we put wedge-shaped bits of foam at the bottom of the seal’s legs. When the seal moves forward, the wedges give no resistance, but when the legs pull back, the wedges stop them.

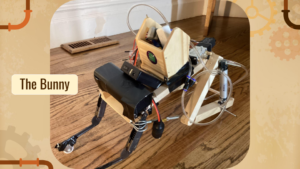

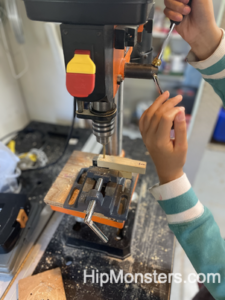

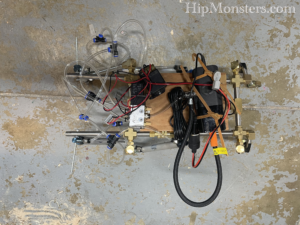

The next robot is our Bunny robot. The bunny robot is also unique because it was originally designed to hop. The two back legs push it forward, thanks to the springs. This one is powered by air and pistons, so you can get the sudden jolt that is harder to achieve with linear actuators. This robot is also one of the only robots made mostly out of wood. We took the idea for the legs from our wooden toys.

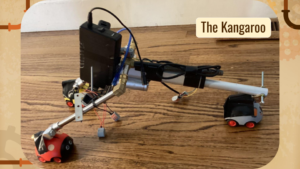

This is the Kangaroo. The kangaroo’s main difference besides the number of legs is the feet. The feet are small animal toys, designed to only go in one direction so they can move forward more efficiently. The back leg powers the whole robot, and we used linear actuators.

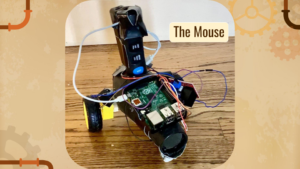

The last robot is the Mouse. The mouse is just a broken blow-dryer attached to wheels from some old toys. It is very simple, so we decided to make it walk on its own, completely uncontrolled and completely randomly, controlled by the Arduino. You can see the code here.

Sorry, this photo was blurry, but the mouse was super fast that day-well charged batteries.

We want to give a big thanks to all who came to our presentation, and everyone who helped and supported us! this was our first big presentation, and we couldn’t be more happy with how it turned out!

Happy creating!

Here is Number Six walking in our yard.

Here is Number Six walking in our yard.