We saw the need for a new robot for Halloween, so we made one. This is our steampunk squirrel powered robot Number Three. We wanted it to be as big as a kid to help with our Halloween decorations. Our other robots were small and not easy to see. Our plan was for a big robot with lights and room to grow as we came up with new ideas.

This post is the very start of Number Three, before we made it move, think, and gave it sensors.

Please note, this material is provided for informational purposes only and is not a guide on how to create the designs. Please read our disclaimer.

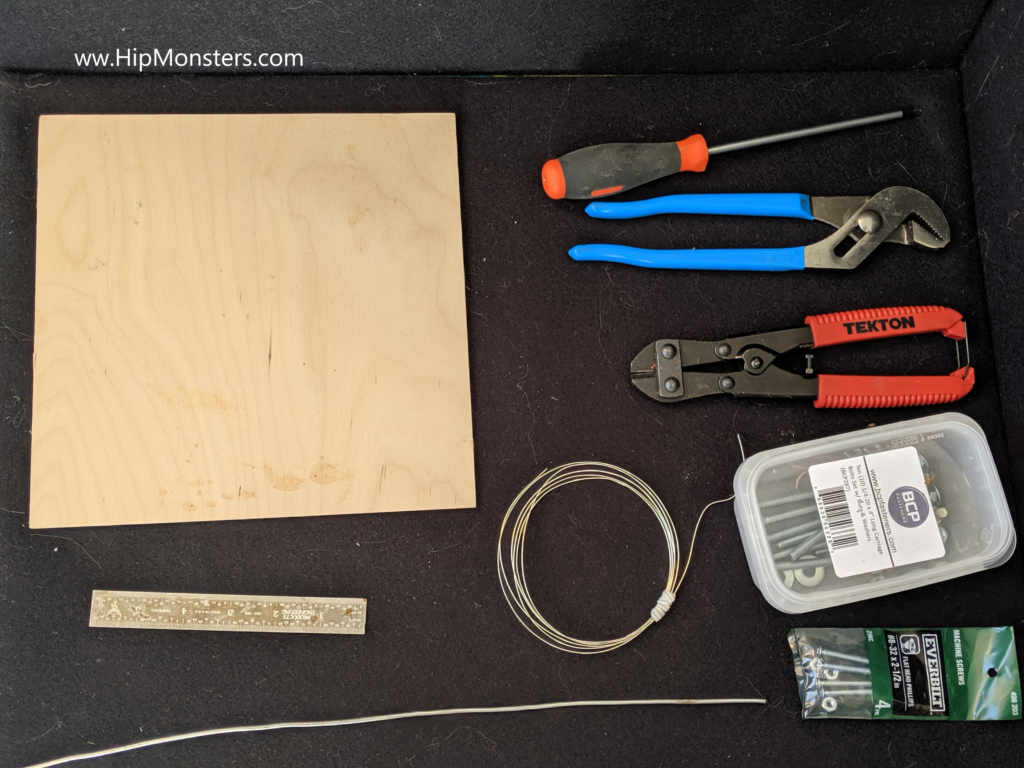

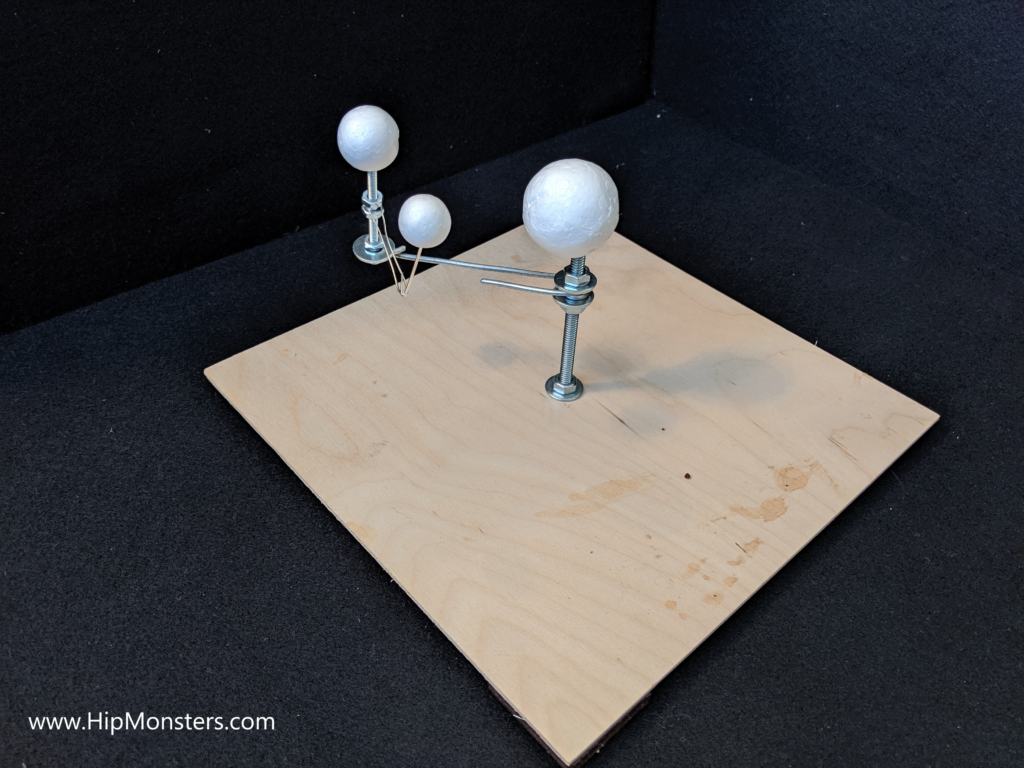

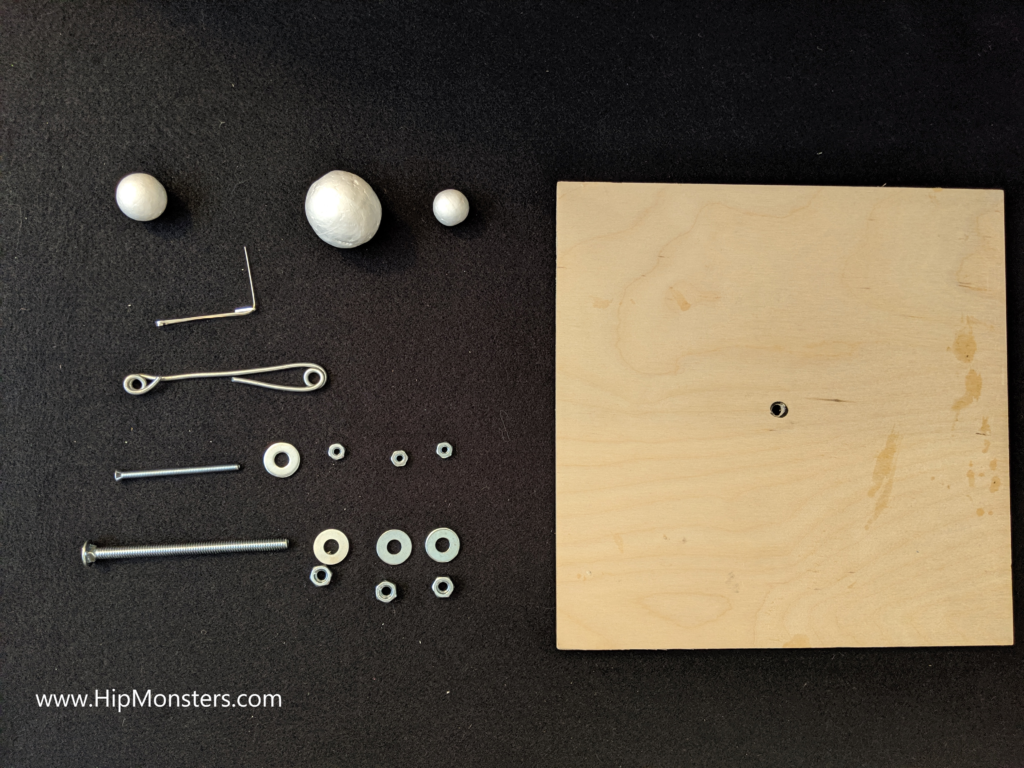

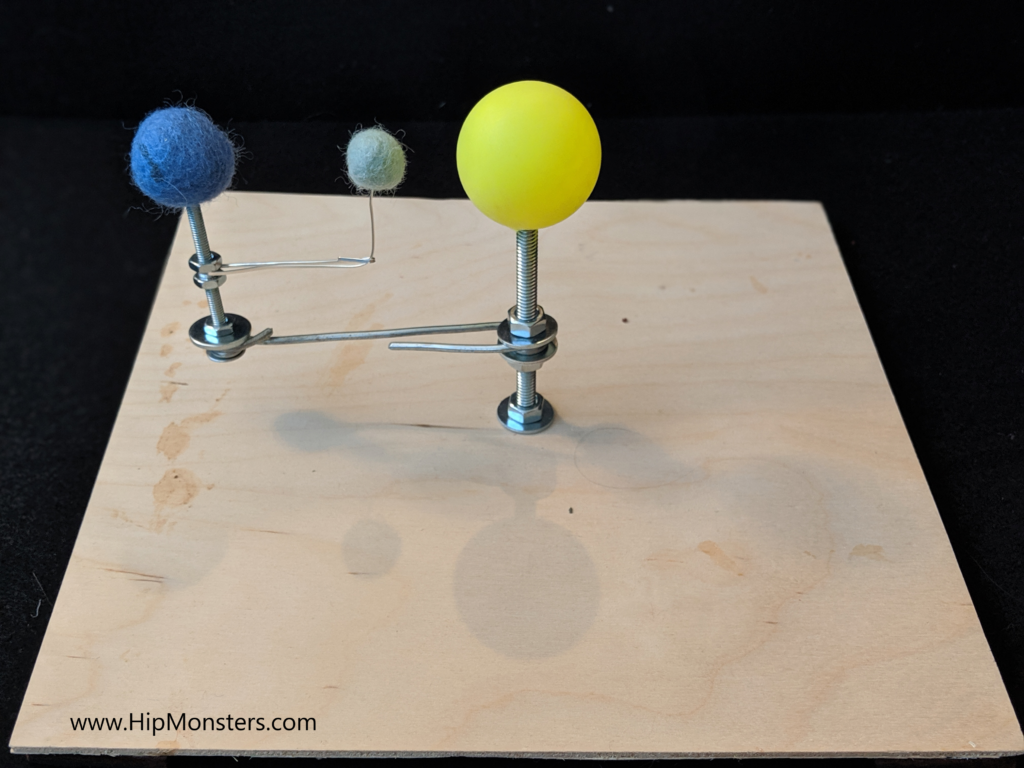

These are some of the parts that we used. We gathered most of it from unused parts from other projects. This project ended up being a great way to recycle old parts and scraps and it made it look even more steampunk-y.

We used PVC pipes for the skeleton of our robot because its strong and lightweight. Also we had fitting from remodeling that would attach to the pipes and let us hangs details. The pipes are standard so if we did need to buy anything it would be easy.

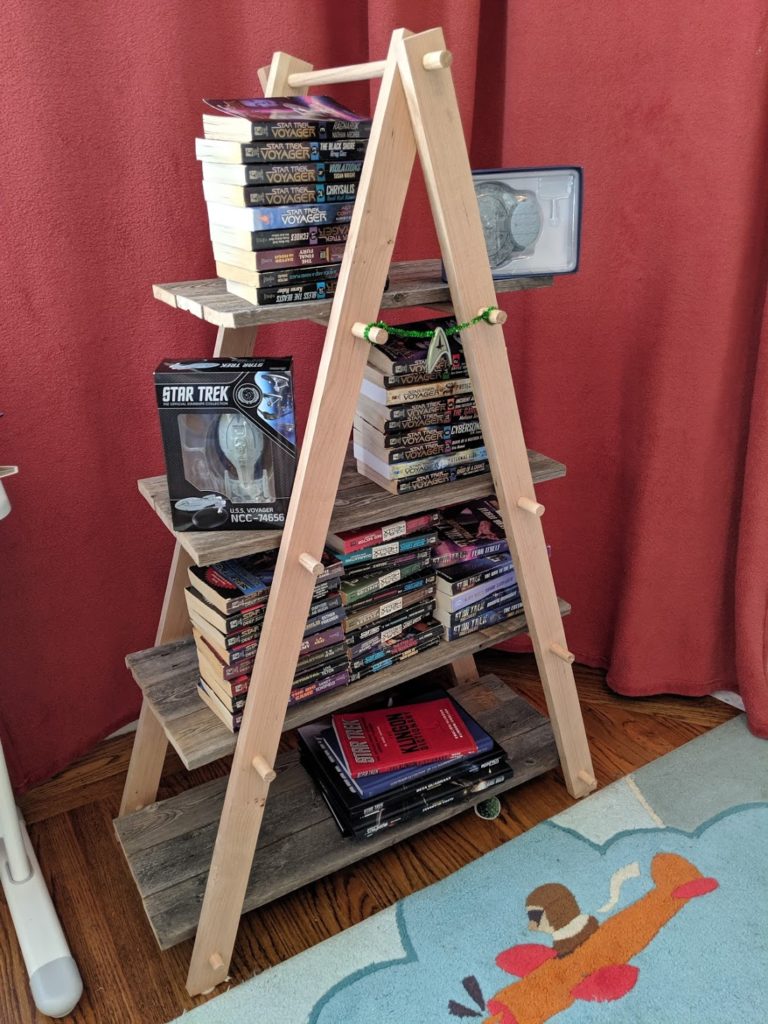

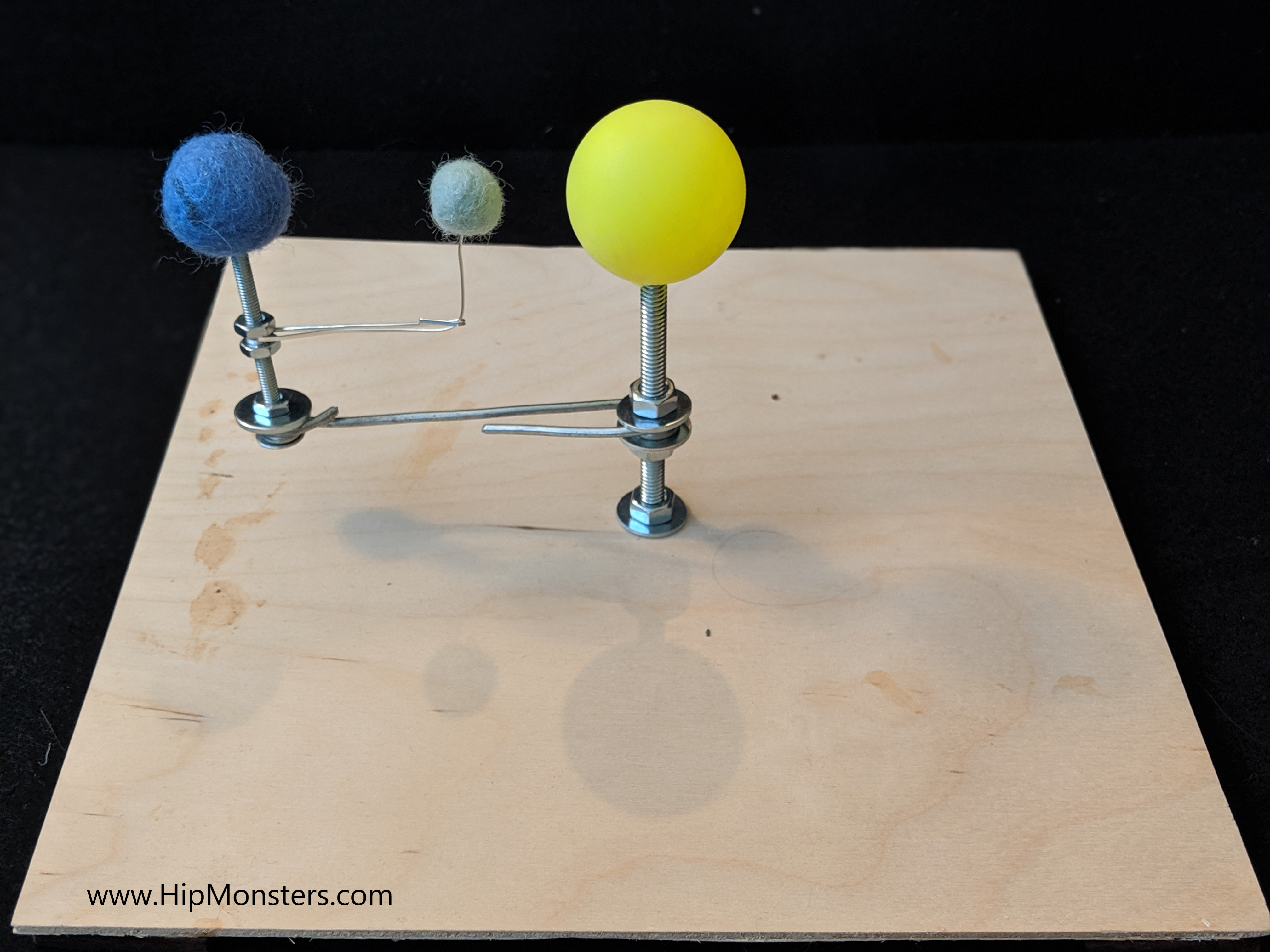

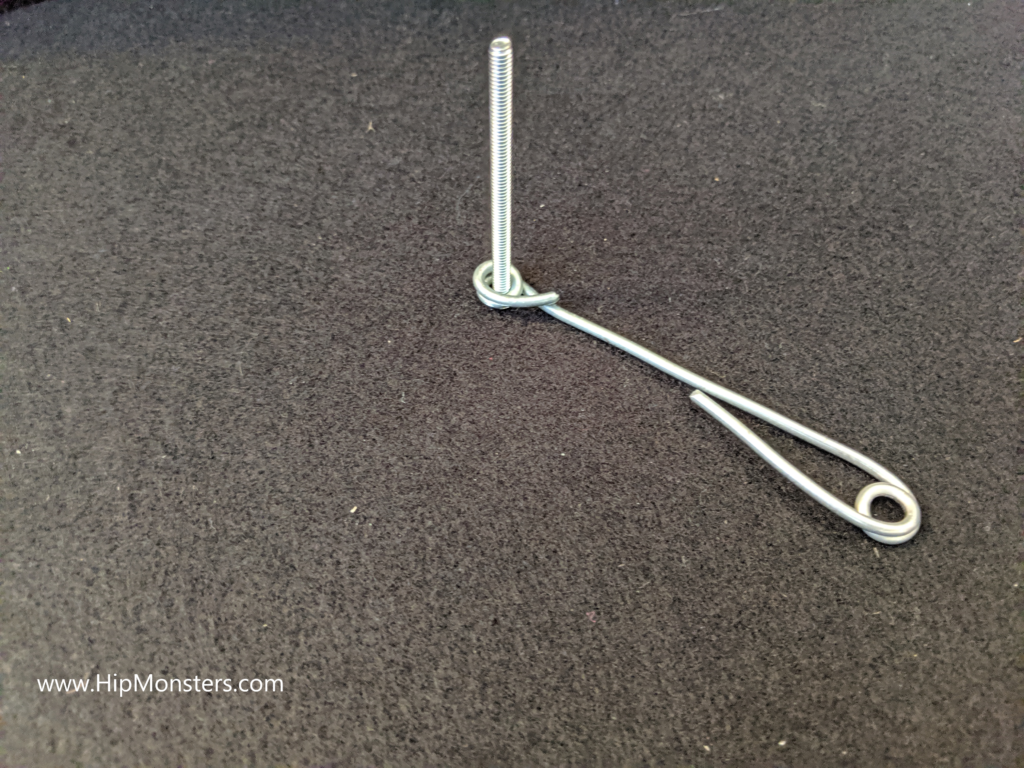

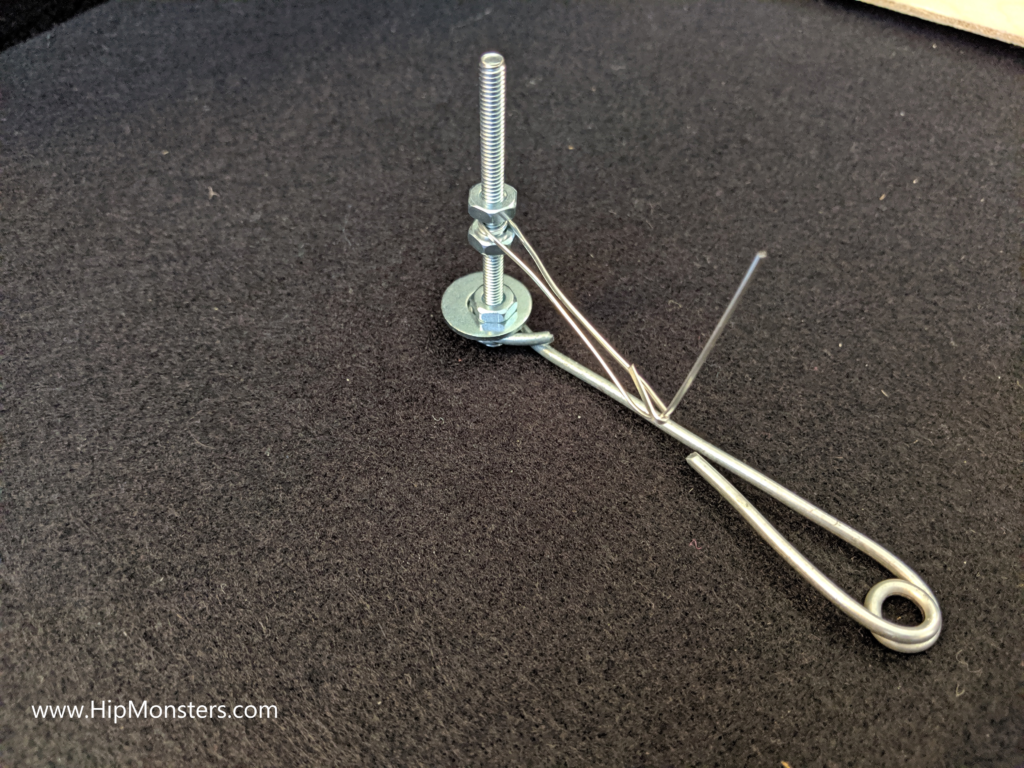

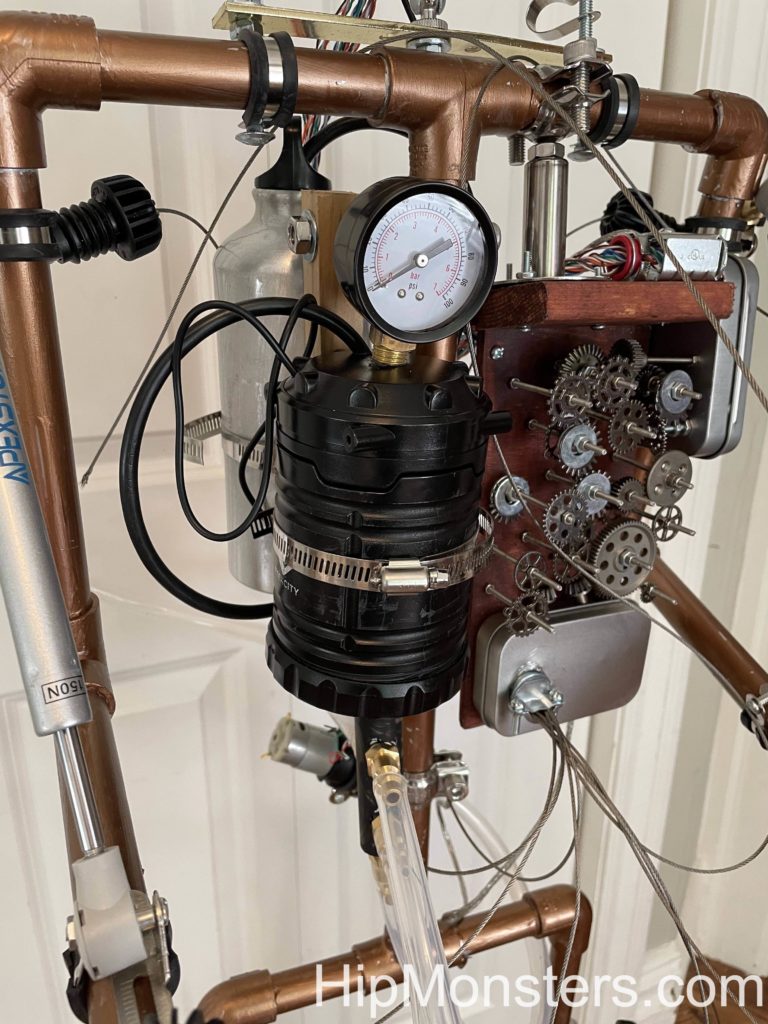

The image to the right is the completed robot. The starting images ended up not as good as we expected so the final image was the best to show how the tubing was used. First, we cut the pipes to the right size using one of us to figure out the length of the arms, legs and spine. Then we assembled it and added feet to keep it stable as we worked. Getting the right balance and weight for the feet was harder than expected. We used concrete bolts with extra washers as needed to weigh them down.

Then we assembled the PVC pipes and painted it with two coats. The first was sliver spray paint; the second was bronze. We did this so when the bronze paint chipped off it would still look like metal instead of plastic. Next, we used an old security camera mount and attached a plastic jar on the neck. We added a toy squirrel inside and a few parts that looked like little controls for it. We named the squirrel Professor Brookenhoff.

For a fake engine core we used an old battery powered lantern connected to an old water bottle.

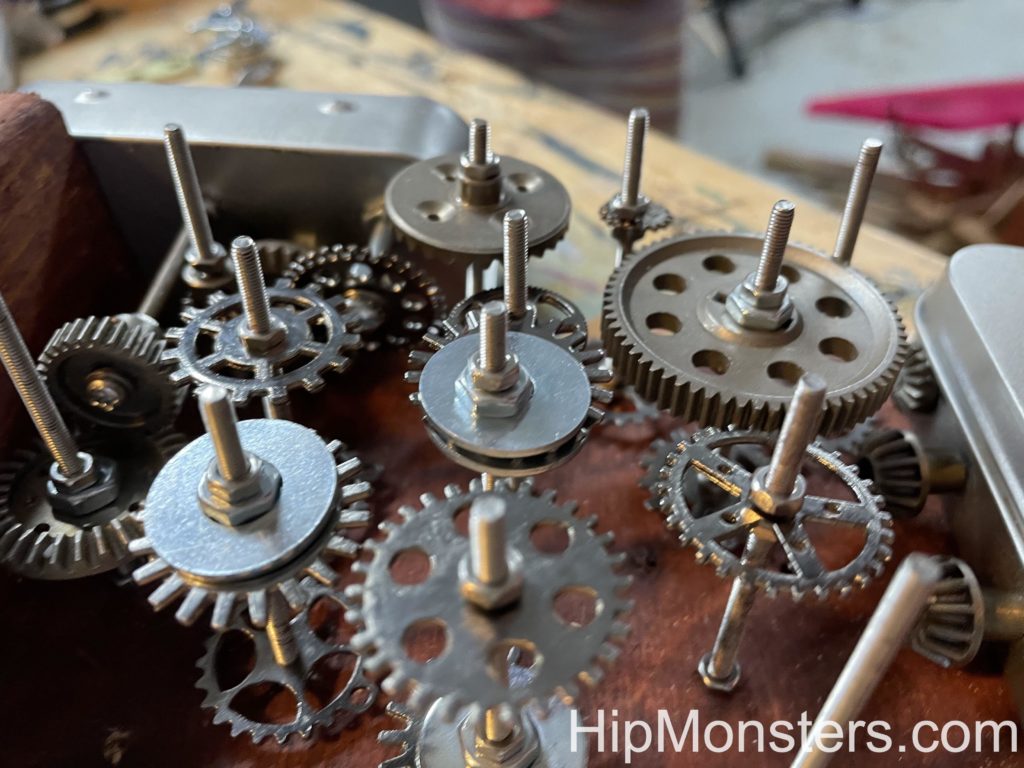

Now we started on the fake control box. To make is steampunk we used gears and only a few wires. Then we assembled the gears to control the robot. We used old wood as a base and stained and distressed it by hitting it with a hammer.

After that, we drilled a bunch of holes on the back and put thin, long bolts through them to create a framework for the gears. Before we assembled it we laid out the gears on the table in the pattern we wanted then transferred the gears to the rig. Remember to lay out the gears in the opposite way you want them in the rig.

Here is a view of gears completed with the control boxes on each side.

The gears took the most time and ended up being a lot harder than we imagined. It was difficult to screw the tiny nuts into place to give it a 3d look. Also, the bolts proved to be sharp. We attached some gears to the side of the control boxes so it would look like they actually controlled the gears.

Then we attached a box to run the wires through. We had a plan on the gears, engine, wire, pistons that we made before we started work that was our best attempt at design an honest working robot. The things we added is what Number Three would have needed if it was real.

We then added a second box next to the gears for attaching the control wires.

Here is a close up of the gears. Getting a 3-D design is important to make it look real. Each gear needs two bolts. One on top and one on the bottom. Make sure they are tightly screwed together.

Now we focused on putting on details that would make it look like Number Three could move. Since it was supposed to be steam powered we used four left over pistons. We attached pneumatic tubing to the pistons then attached the other end to the engine. The idea is the power from the engine would create steam, and Professor Brookenhoff would give commands to the gears which would send the steam to the right piston to make it move. The idea of the head came from Carmichael from The Umbrella Academy.

As we added more details to Number Three, we also needed to add more heavy things to the feet for stability.

A close up of Professor Brookenhoff piloting Number Three.

A close up of the tubing from the engine to the joints.

Number Three from side view. Here you can see the hands which also ended up being hard to make. Finally we made the hands out of wires and springs so it can hold things.

Here is the completed Number Three.

Happy Creating!